Aluminum 3D printing is revolutionizing the manufacturing game, and it’s not just for tech geeks anymore. Imagine crafting lightweight, durable parts that can withstand the test of time—all while sipping your coffee and watching your printer work its magic. This technology isn’t just a fad; it’s a game-changer for industries ranging from aerospace to automotive.

Table of Contents

ToggleWhat Is Aluminum 3D Printing?

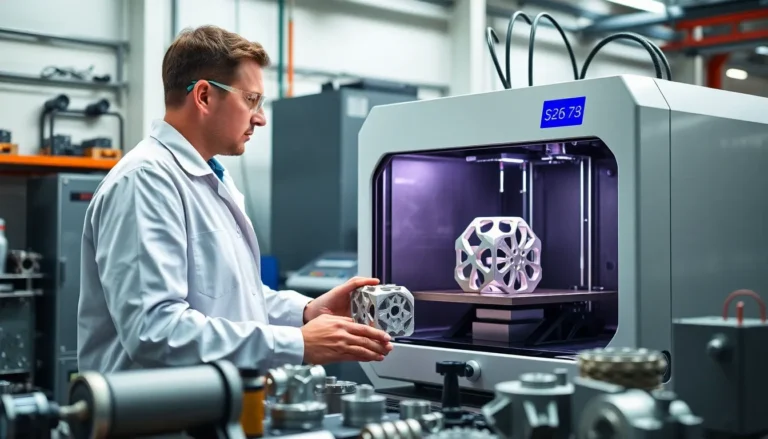

Aluminum 3D printing, also known as metal additive manufacturing, allows for the creation of complex components using aluminum materials. This process utilizes layers of aluminum powder or wire, which a laser or electron beam melts to form objects. Notably, this technique supports the production of intricate designs that traditional manufacturing methods struggle to achieve.

Manufacturers appreciate this approach for its efficiency in producing lightweight and strong components suited for demanding applications. Common industries benefiting from aluminum 3D printing include aerospace, automotive, and medical sectors. Each industry utilizes aluminum 3D printing to achieve high-performance parts with reduced weight, often enhancing fuel efficiency or reducing costs.

The technology incorporates several methods, such as Direct Energy Deposition (DED) and Selective Laser Melting (SLM). These methods differ in how they fuse aluminum particles together, impacting finish quality and material properties. Each method gives designers the flexibility to choose based on specific requirements.

Cost-effectiveness stands out as another significant advantage. Rather than relying on extensive tooling or molds, aluminum 3D printing decreases material waste and shortens lead times. An array of companies now offers accessible solutions, enabling smaller businesses to harness this innovative technology.

As more companies adopt this technology, the applications continue to expand. Considering this, aluminum 3D printing’s versatility and capability not only revolutionizes manufacturing processes but also encourages innovation across multiple sectors.

Benefits of Aluminum 3D Printing

Aluminum 3D printing offers significant advantages for various applications, making it a preferred choice in multiple industries. These benefits include lightweight construction, strength, and corrosion resistance.

Lightweight and Strong

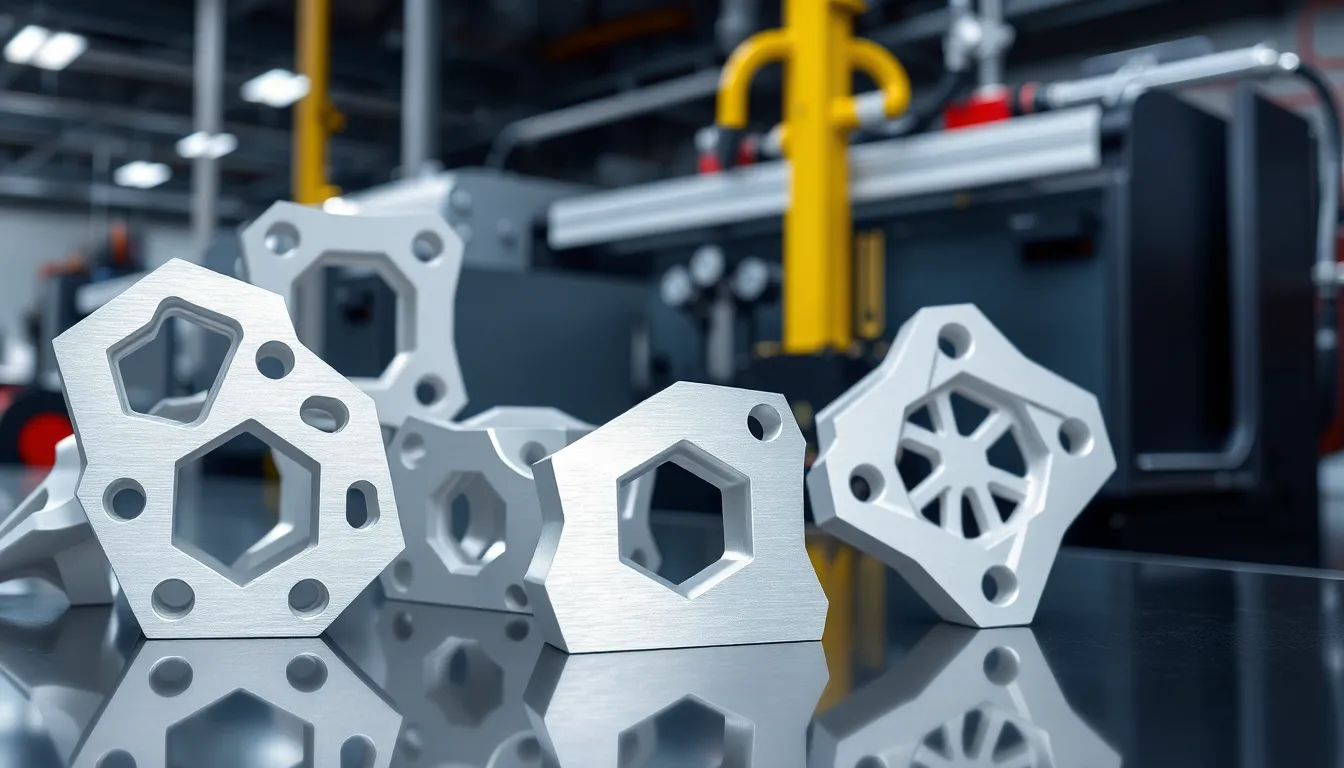

Parts created through aluminum 3D printing boast an excellent strength-to-weight ratio. Manufacturers use aluminum alloys like 6061 and 7075, which provide remarkable strength without excess weight. Designers appreciate how complex geometries can maintain integrity while reducing mass, crucial for applications in aerospace and automotive. Each component exhibits durability, enabling components to withstand high stress and temperature variations. Innovative designs support lighter structures, thereby enhancing fuel efficiency and overall performance.

Corrosion Resistance

Corrosion resistance is another critical benefit of aluminum 3D printing. This material naturally resists oxidation, making it suitable for environments prone to moisture and chemical exposure. Components produced using aluminum maintain their appearance and structural integrity longer than many other metals. Industries such as marine and automotive frequently prefer aluminum for its ability to resist rust and degradation over time. Protective coatings can further enhance this property, extending the lifespan of finished parts in demanding conditions.

Applications of Aluminum 3D Printing

Aluminum 3D printing finds numerous applications across various sectors, showcasing its versatility and innovative capabilities.

Aerospace Industry

In the aerospace industry, aluminum 3D printing plays a crucial role in fabricating lightweight yet durable components. The ability to create complex geometries makes it possible to design parts that reduce overall weight without compromising strength. Components like brackets and housings benefit from this technology, leading to enhanced fuel efficiency. Companies utilize aluminum alloys such as 7075 for their impressive strength-to-weight ratios. Furthermore, the fast prototyping capabilities improve the development of airframes and engine components, accelerating project timelines.

Automotive Industry

The automotive industry embraces aluminum 3D printing for producing various lightweight parts, which significantly impacts vehicle performance. This technology allows manufacturers to create intricate designs that traditional methods cannot achieve. Components like engine mounts, suspension parts, and exhaust systems are now made with aluminum 3D printing techniques. Designers appreciate the efficiency of creating customized parts that meet specific requirements quickly. Use of aluminum alloys contributes to maintaining strength while reducing mass, resulting in improved fuel economy and handling.

Medical Devices

In the realm of medical devices, aluminum 3D printing revolutionizes the creation of lightweight, high-performance components. Devices like surgical instruments and implants benefit from precise customization, ensuring better patient outcomes. Production processes allow for intricate designs that enhance functionality while minimizing weight. Strong and corrosion-resistant aluminum alloys make these devices durable in varied environments. By leveraging this technology, manufacturers can quickly adapt designs for specific medical applications, further advancing innovation in healthcare solutions.

Challenges of Aluminum 3D Printing

Aluminum 3D printing presents various challenges that manufacturers must navigate. Addressing these issues ensures successful implementation and optimal results in production.

Material Properties

Material properties pose a significant challenge in aluminum 3D printing. Aluminum alloys exhibit differences in thermal conductivity, which affects cooling rates during printing. Poor thermal management can lead to warping or cracking in printed parts. Additionally, the mechanical properties of aluminum can vary based on the specific alloy used and the printing method. Variations in density and structural integrity may occur, impacting the final product’s performance. To maintain quality, careful selection of aluminum alloys like 6061 and 7075 is crucial.

Post-Processing Requirements

Post-processing requirements add complexity to the aluminum 3D printing workflow. Many printed parts require additional steps such as heat treatment, machining, or surface finishing to achieve desired specifications. Heat treatment enhances strength and ductility but can compromise the dimensional accuracy of the part. Machining is often necessary to improve surface quality or fine-tune critical dimensions. Surface finishing techniques, like anodizing, improve corrosion resistance but require precise handling. Thorough planning for these post-processing stages is essential to meet performance standards while managing production timelines.

Future Trends in Aluminum 3D Printing

Ongoing advancements in aluminum 3D printing technology promise to redefine manufacturing capabilities. Innovations in design software will enhance users’ ability to create intricate geometries that optimize material usage while improving performance. Increased automation is expected to streamline production processes, reducing lead times and enhancing efficiency.

Emerging materials play a crucial role in these trends, with new aluminum alloys engineered specifically for additive manufacturing. These alloys will exhibit improved strength, durability, and heat resistance, catering to more demanding applications. Increased collaboration between manufacturers and researchers will facilitate the development of these specialized materials.

Sustainability continues to be a significant focus, driving the adoption of aluminum recycling in 3D printing. Companies will implement strategies that aim to minimize waste and promote circular economy practices. As the industry grows, educational initiatives will become vital, ensuring that the workforce is skilled in using advanced technologies and materials.

Applications of aluminum 3D printing will expand beyond traditional uses. Industries such as construction may explore additive manufacturing for customizable structures and components. Aerospace applications are likely to embrace the technology for lighter aircraft designs, further enhancing fuel efficiency.

Competition among manufacturers can accelerate innovation, leading to faster advancements in printing technologies and techniques. Expect to see developments in hybrid processes that combine traditional and additive methods, offering greater flexibility in production.

Overall, perpetual improvements in aluminum 3D printing tools will empower diverse industries to embrace this technology, ultimately enhancing efficiency, reducing costs, and fostering sustainable practices.

Aluminum 3D printing is reshaping the landscape of manufacturing with its unique capabilities and advantages. As industries embrace this technology, they unlock new possibilities for creating lightweight and durable components that enhance performance and efficiency. The ongoing innovations in design and materials promise to further expand its applications across various sectors.

Challenges remain in the form of material properties and post-processing requirements. However, with careful planning and advancements in technology, manufacturers can overcome these hurdles. The future of aluminum 3D printing looks bright as it continues to drive innovation and sustainability, paving the way for a new era in manufacturing.