In the ever-evolving world of manufacturing, DMLS 3D printing is like the cool kid at school who just invented a new game. Direct Metal Laser Sintering takes metal 3D printing to a whole new level, allowing engineers and designers to create complex, high-performance parts that traditional methods can only dream of. Imagine crafting intricate shapes that fit together like a perfectly choreographed dance—it’s not just magic; it’s DMLS!

But wait, there’s more! This technology isn’t just about looking good; it’s about performance. From aerospace to healthcare, DMLS is revolutionizing industries by offering lightweight yet durable components. If you thought 3D printing was just for plastic toys and quirky gadgets, think again! Dive into the fascinating world of DMLS and discover how this cutting-edge technique is reshaping the future of production.

Table of Contents

ToggleOverview of DMLS 3D Printing

Direct Metal Laser Sintering (DMLS) represents a vital advancement in 3D printing technology. This method uses a high-powered laser to fuse powdered metal into solid structures. Applications of DMLS span various industries, including aerospace, automotive, and medical. Significant benefits include the ability to create intricate geometries that traditional methods cannot achieve.

Materials used in DMLS include titanium, aluminum, and stainless steel. Each material brings distinct properties suited for specific applications. For example, titanium parts offer strength and corrosion resistance, making them ideal for aerospace components. In contrast, aluminum parts provide lightweight solutions for automotive applications.

DMLS technology operates using a layer-by-layer approach, allowing for greater design flexibility. Designers and engineers can optimize components for weight reduction and improved performance. This capability results in products that meet stringent industry standards while minimizing material waste.

Sintered parts exhibit excellent mechanical properties, making them suitable for functional testing and end-use applications. The durable nature of DMLS parts leads to enhanced product longevity. Cost efficiency becomes apparent as DMLS reduces lead times and material costs for low-volume production runs.

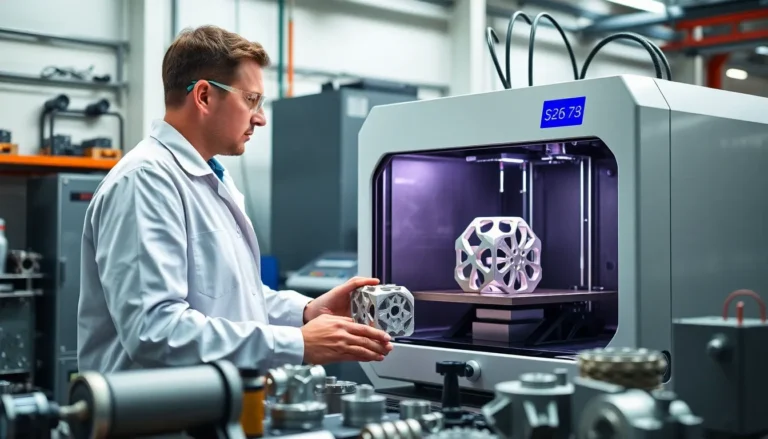

Various companies now utilize DMLS machines to enhance their manufacturing processes. These machines integrate seamlessly into existing workflows, supporting rapid prototyping and production. As a result, organizations find themselves improving overall production efficiency and product quality.

DMLS 3D printing stands out as a transformative technology crucial for modern manufacturing challenges, continuously pushing the boundaries of what is achievable.

How DMLS 3D Printing Works

DMLS 3D printing utilizes a precise technique to transform powdered metal into solid parts. This method showcases its unique capabilities through each step of the process.

The Process Explained

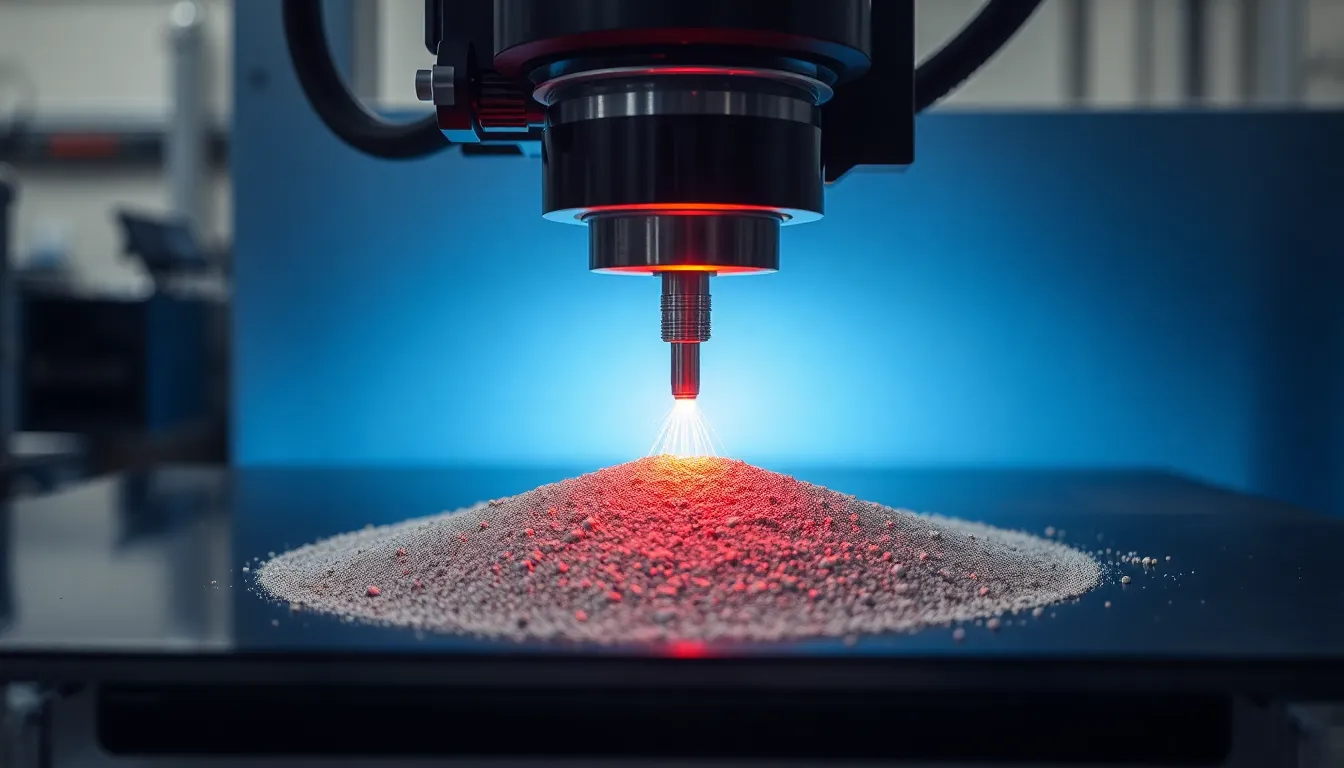

A high-powered laser melts metal powder, fusing particles together layer by layer. Each layer builds on the previous one, creating complex geometries that are difficult to achieve with traditional methods. Precision is paramount, as the laser’s focus and movement dictate the final structure’s accuracy. Once the build is complete, the un-sintered powder is removed, revealing intricately designed components ready for use. This efficient approach allows DMLS to produce functional parts directly from digital models, reducing the need for extensive tooling.

Required Materials

DMLS employs various metal powders tailored to specific applications. Titanium is lightweight yet strong, making it ideal for aerospace components. Aluminum provides excellent thermal conductivity, suitable for automotive applications. Stainless steel offers remarkable corrosion resistance, often utilized in medical devices. Each material presents unique properties that enhance performance and longevity. Quality control for the powders is crucial, as particle size and distribution affect the sintering process. Understanding material selection ensures DMLS achieves optimal results in diverse industrial sectors.

Benefits of DMLS 3D Printing

DMLS 3D printing offers significant advantages, transforming manufacturing capabilities across industries. This technology optimizes production processes and enhances the properties of manufactured parts.

Design Flexibility

Design flexibility represents a key benefit of DMLS. This method produces complex geometries that traditional manufacturing can’t achieve. Designers explore innovative shapes and structures, enabling solutions tailored for specific applications. The layer-by-layer construction allows for rapid adjustments during the design phase, promoting creativity. Customization becomes feasible without incurring high costs or lengthy lead times. Consequently, engineers can optimize weight and performance, ultimately leading to more efficient end products.

Material Strength and Durability

Material strength and durability stand out as critical benefits of DMLS 3D printing. Parts created through this technology possess superior mechanical properties due to the fusion process of powdered metals. High-performance materials like titanium and stainless steel yield components that withstand demanding conditions. DMLS components exhibit incredible toughness and resilience, proving suitable for aerospace and automotive applications. The density of sintered materials enhances their durability, promoting longer product life cycles. Overall, DMLS ensures that end products not only meet but exceed industry performance standards.

Applications of DMLS 3D Printing

DMLS 3D printing shows versatility across various industries, allowing for the production of intricate and high-performance components.

Aerospace Industry

Aerospace applications benefit significantly from DMLS technology. Lightweight yet strong titanium parts contribute to improved fuel efficiency and performance in aircraft. Engineers design complex geometries, such as lattice structures, which minimize weight without sacrificing strength. Components created with DMLS undergo rigorous testing to ensure they meet stringent industry standards. Additionally, reduced lead times enable faster prototyping and deployment of innovative designs, which is crucial in the competitive aerospace market.

Medical Sector

The medical sector leverages DMLS for producing customized implants and surgical tools. Biocompatible materials like titanium enable the creation of personalized prosthetics tailored to individual patient needs. Customization enhances the fit and comfort of implants, improving patient outcomes. Moreover, complex geometries in tools facilitate minimally invasive surgeries, leading to shorter recovery times. DMLS technology also supports the rapid development of medical devices, ensuring that healthcare providers have access to cutting-edge solutions.

Challenges and Limitations of DMLS 3D Printing

DMLS 3D printing faces several challenges that impact its broader adoption. High equipment costs represent a significant barrier for many companies, requiring substantial initial investment in DMLS machines. Maintenance expenses can also be considerable due to the need for specialized personnel and ongoing operational costs.

Material limitations affect the process as well. While DMLS supports materials like titanium, aluminum, and stainless steel, the range of compatible alloys is less extensive compared to traditional methods. Some applications require specific material properties that DMLS doesn’t currently meet.

Part defects arise during the sintering process. Issues such as porosity and inadequate fusion can compromise the quality of the final products, leading to structural weaknesses. Regular quality control and thorough inspections are essential to mitigate these defects, adding to operational complexity.

The speed of production presents another challenge. Although DMLS allows for intricate designs, build times can be lengthy, particularly for larger components or complex geometries. This slower pace may not align with rapid prototyping needs in fast-paced industries.

Design constraints also exist. Certain geometries may not be feasible in DMLS due to support requirements or the limitations of powder metallurgy. Adjusting designs to accommodate these constraints can complicate workflows and necessitate additional engineering efforts.

Post-processing requirements contribute to time and cost challenges. Various steps, including heat treatment and surface finishing, are often necessary to achieve desired mechanical properties and surface characteristics. These processes can significantly extend lead times, reducing the overall efficiency of DMLS production runs.

Collectively, these challenges and limitations necessitate careful consideration when integrating DMLS into manufacturing processes, ensuring that its advantages align with specific production goals.

DMLS 3D printing stands at the forefront of modern manufacturing technology. Its ability to create complex metal parts with precision opens new avenues for innovation across various industries. By leveraging unique material properties, DMLS enhances performance while reducing waste and production costs.

Despite its challenges, including equipment costs and material limitations, the benefits of DMLS make it a compelling choice for businesses seeking to optimize their manufacturing processes. As more companies adopt this technology, it’s likely to reshape traditional production methods and drive advancements in design and functionality. The future of DMLS promises exciting developments that could redefine how industries approach manufacturing.