In a world where everything needs a label and every product demands a unique identity, laser coding machines have stepped into the spotlight like a superstar at a concert. These high-tech marvels don’t just mark products; they create masterpieces of precision and clarity. Imagine a machine that can etch your brand’s name onto a bottle faster than you can say “quality assurance.” That’s the magic of laser coding!

Table of Contents

ToggleOverview Of Laser Coding Machines

Laser coding machines play a crucial role in the manufacturing sector by delivering precise markings on products. These machines streamline the branding process and improve traceability while ensuring compliance with regulations.

What Is A Laser Coding Machine?

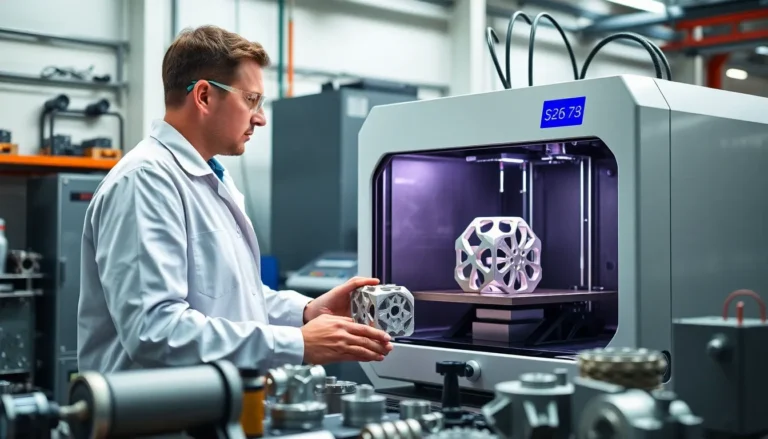

A laser coding machine utilizes focused laser beams to engrave or mark materials. It permanently etches text, logos, and barcodes onto various surfaces. Common applications include packaging, pharmaceuticals, and food items due to the durability of the markings. Manufacturers value these machines for their speed and efficiency, as they can achieve high throughput without compromising quality.

Key Components Of Laser Coding Machines

Several key components contribute to the functionality of laser coding machines. The laser generator produces beams that engrave onto surfaces. A motion system controls the movement of the laser head, ensuring accuracy across different materials. Additionally, the software interfaces allow operators to design and modify codes easily. Cooling systems prevent overheating during operations, enhancing the machine’s reliability. Collectively, these components enable laser coding machines to deliver consistent performance across a variety of applications.

Benefits Of Using Laser Coding Machines

Laser coding machines offer multiple advantages that significantly impact manufacturing processes and product marketing. These benefits include superior precision, improved traceability, and long-term cost savings.

Precision And Accuracy

Precision defines laser coding machines. Markings generated through laser technology ensure high clarity and sharpness. These machines engrave details like barcodes and logos with remarkable accuracy, reducing the chances of errors. Consistency is a key factor, as laser coding maintains uniformity in each marking, leading to reliable identification across products. Complex designs become achievable, allowing brands to display intricate logos effectively. Manufacturers often choose laser coding for its superior performance, confident that their products will stand out without compromising on quality.

Cost-Effectiveness Over Time

Long-term cost savings characterize the financial benefits of laser coding machines. Initial investments might seem considerable, but the durability of laser markings translates into reduced need for replacements or repairs. Unlike traditional coding methods, these machines don’t require consumables like inks or ribbons, minimizing ongoing operational costs. Maintenance expenses also decrease, as laser systems often demand less frequent servicing. Manufacturers recognize that the lifespan of these machines contributes to overall savings, positioning laser coding as a wise choice in an evolving market. Long-term calculations consistently reveal the cost advantages, solidifying the machines’ importance in efficient production lines.

Applications Of Laser Coding Machines

Laser coding machines play a vital role across various industries, showcasing their versatility and efficiency in product marking.

Packaging Industry

In the packaging industry, laser coding machines provide high-resolution markings on various materials like plastic, cardboard, and glass. These markings include expiration dates, batch numbers, and barcodes, ensuring that products meet regulatory requirements. Automated systems generate real-time data that enhance supply chain efficiency. Increased speed prevents production bottlenecks, while the durability of laser markings withstands harsh shipping conditions. Industries utilizing these machines minimize waste and ensure products remain traceable through automated tracking systems.

Electronics Manufacturing

Electronics manufacturing benefits significantly from laser coding machines, especially for marking components like circuit boards and casings. Precise engravings allow for clear identification of brand logos, serial numbers, and QR codes. These machines offer a non-contact solution that prevents damage to sensitive electronic parts. Quick setup times facilitate a seamless integration into production lines, significantly increasing throughput. By ensuring that markings remain intact despite environmental factors, manufacturers can maintain quality control and enhance product reliability.

Choosing The Right Laser Coding Machine

Selecting a suitable laser coding machine involves multiple considerations to ensure optimal functionality and efficiency for specific applications.

Factors To Consider

Budget remains a crucial element when deciding on a laser coding machine. Organizations must evaluate initial investment alongside long-term operational costs. Production volume directly impacts the machine’s capacity. Identifying the required marking speed and accuracy enables better alignment with operational goals. Compatibility with various materials is essential, especially for industries like packaging and electronics, which require different marking substrates. Finally, assessing maintenance needs and support services guarantees reliability over time.

Comparing Different Models

Evaluating various laser coding machine models aids in making an informed decision. Specifications and features vary considerably, so organizations should prioritize those that align with specific production needs. For example, fiber lasers excel with metal and plastic, while CO2 lasers are ideal for organic materials. Comparison of marking speed, power output, and resolution helps highlight differences in performance. User-friendly interfaces and software capabilities contribute to operational ease. Additionally, considering warranty terms and customer service can enhance overall satisfaction and reduce potential downtime.

Laser coding machines represent a pivotal advancement in manufacturing and branding. Their ability to deliver precise and durable markings not only enhances product visibility but also ensures compliance with industry standards. As businesses strive for efficiency and quality, investing in these machines proves beneficial in the long run.

With their versatility across various sectors—from packaging to electronics—laser coding machines streamline processes and improve traceability. Organizations can achieve significant cost savings while maintaining high standards of clarity and precision in their markings. Choosing the right model tailored to specific needs can further optimize production capabilities, making laser coding machines an essential tool for modern manufacturers.